To solve defects such as streaks, micro-pits, and wavy shapes on the surface of welding wire, targeted treatments should be carried out from three core links: mold optimization, process parameter adjustment, and raw material control. The specific solutions are as follows:

1. Prioritize addressing "mold-related" issues (core influences such as streaks and micro-pits)

- Mold surface and precision repair: If there is wear, scratches or insufficient processing accuracy on the inner wall of the mold, it will directly press out streaks or cause uneven metal flow and form micro-pits. The inner wall of the mold needs to be polished regularly (it is recommended to use a diamond grinding wheel for fine polishing to Ra≤0.05μm), and the roundness and taper of the mold holes should be checked to ensure they match the specifications of the welding wire.

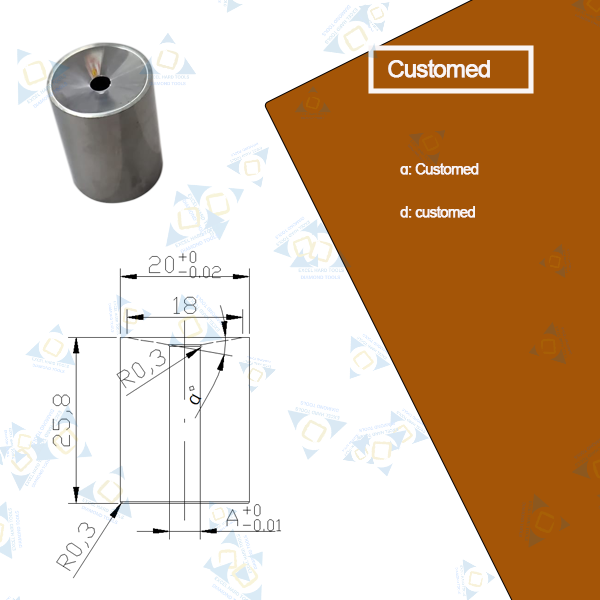

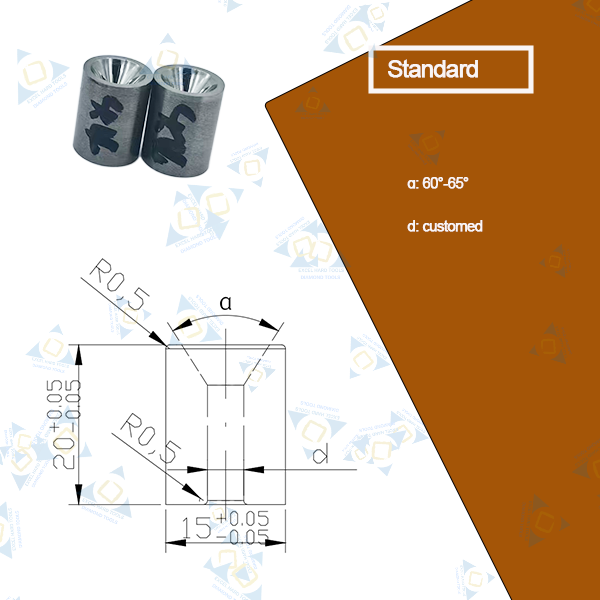

- Replace the suitable fine-grained cemented carbide mold: Select the ultra-fine-grained cemented carbide mold mentioned earlier (such as WC particle size 0.5-1μm), which has a higher surface finish and stronger wear resistance, can reduce the frictional resistance between the metal and the mold, and avoid the formation of streaks due to rapid mold wear.

- Optimize die arrangement and lubrication: During multi-pass drawing, ensure that the die center is coaxial with the wire direction (deviation ≤0.02mm) to avoid wavy shapes caused by eccentric drawing. At the same time, use high-purity and low-impurity drawing lubricants (such as synthetic lubricants) to reduce the residue of metal chips and prevent the formation of micro-pits.

2. Adjust the "drawing/rolling process parameters" (the core influences wavy shapes and micro-pits)

- Control the deformation amount and speed: Excessive deformation in a single drawing (exceeding 30%) will cause stress concentration in the welding wire, resulting in a wavy shape. Excessive speed (exceeding 15m/s) can easily lead to insufficient lubrication and the formation of micro-pits. It is recommended to control the single deformation amount at 15%-25%, and adjust the drawing speed according to the material of the welding wire (such as ER50-6) to ensure uniform metal flow.

- Stable temperature and tension: If the cooling is insufficient during the drawing process and the temperature of the welding wire is too high (exceeding 80℃), it will cause surface oxidation or softening, forming micro-pits. Fluctuations in the tension during wire winding (with a deviation exceeding 5%) will cause uneven stretching of the welding wire, resulting in a wavy shape. A cooling water circuit needs to be installed (ensuring the water temperature is ≤30℃), and a constant tension winding system should be adopted.

3. Strengthen "raw material pretreatment" (reducing defect causes at the source)

- Control the quality of the welding wire billet: If the surface of the billet has oxide scale, cracks or inclusions, it will turn into micro-pits or streaks after drawing. The billet needs to undergo acid washing (to remove the oxide scale) and flaw detection (to eliminate internal defects) to ensure that the surface finish of the billet is Ra≤1.6μm and there are no visible impurities to the naked eye.

- Optimize the pretreatment before coating: If defects are exposed during the coating process, an additional "electrolytic polishing" or "sandblasting treatment" procedure should be added before coating to remove the tiny defects on the surface of the welding wire and simultaneously increase the surface roughness (Ra controlled at 0.8-1.2μm), indirectly improving the adhesion of the coating.

4. Auxiliary "online detection and post-processing" (safety net guarantee)

Install an online visual inspection system (such as CCD camera +AI recognition) to monitor the surface of the welding wire in real time. Once a defect is detected, stop the machine immediately for adjustment to avoid batch defects.

For welding wires with minor defects, "light drawing repair" (with a single deformation of 5%-8%) or "low-temperature tempering" (200-250℃, holding for 1 hour) can be adopted to eliminate some stress and reduce the influence of wavy shapes.

Through the above steps, streaks, micro-pits and wavy defects can be reduced from the source, thereby enhancing arc stability (reducing current fluctuations caused by surface irregularities) and coating adhesion (eliminating coating bonding gaps caused by defects).