Cable wire extrusion die is a key component used in the wire and cable production process, its main function is to extrude plastic or other insulating material through the die to produce wire and cable products that meet the specifications. The design and manufacturing quality of molds directly affect the quality of products and production efficiency.

Classification and characteristics of extrusion dies

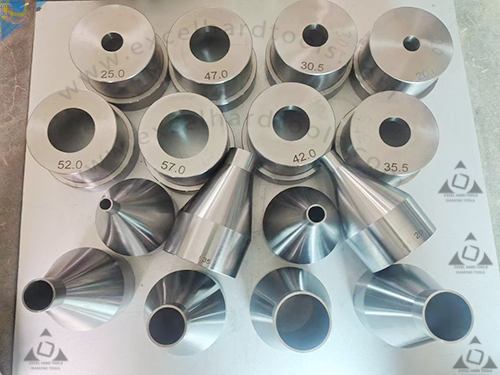

Cable and wire extrusion dies can be classified into the following three types based on the fit between the die core and the die sleeve:

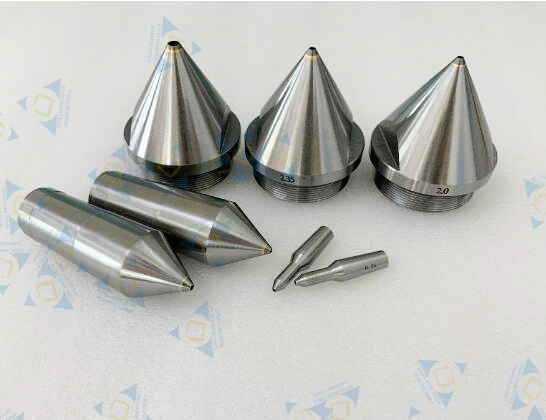

Extrusion die : This type of die has a constant diameter at the front end of the die core and is suitable for wires and cables that require uniform extrusion. Extrusion die relies on a large extrusion pressure to shape the product, the extrusion pressure is high, the product is tight, the strength is reliable, but the accuracy of the die is required to be higher .

Tube extrusion die : The diameter of the front end of the die core varies, suitable for wires and cables that require specific shapes or sizes. Extrusion tube die extrusion pressure is relatively small, suitable for the irregular core situation, such as sheath outside armor or insulation of fire-resistant cable, etc.

Semi-extrusion die : This die combines the features of extrusion and tube extrusion and is suitable for specific process requirements. The core of the semi-extrusion die has a tubular bearing section but is shorter, is a transitional form between the extruded tube type and the extruded type .

The role of molds in the production of wires and cables

Molds play a crucial role in the production of wires and cables. Its geometric shape, structural type and size, temperature level, pressure magnitude and other factors directly determine the processing quality of the product. Die is the final hot press device in the extrusion process, and its design, fitting and insulation measures are highly valued .

Application scenarios of different types of molds

Extrusion die : Suitable for wires and cables that require uniform extrusion, such as ordinary insulated wires.

Tube extrusion die: Suitable for irregular core conditions, such as sheath outside armor or insulation of fire-resistant cables.

Semi-extrusion die : Suitable for specific process requirements, is a transitional form between tube extrusion and extrusion.