Product Name:NANO Diamond Drawing

Dies;NANO/CVD Diamond

Die;NANO Diamond Coated Dies

Hole Sizes:0.65-75.000(mm)

Applications:Copper wire,aluminum wire,wire and cable,stainless steel wire,medium and low carbon steel wire,stainless steel wire,low carbon steel wire,copper pipe,aluminum pipe,stainless steel pipe,etc.

Blank Type: CVD/Nano diamond

CVD (Chemical Vapor Deposition) Coated Wire Drawing Die is a new technology that has been developed recently, and its main method is to coat diamond film on the hard alloy wire drawing die. The diamond film is pure diamond polycrystalline. It not only has the smoothness and temperature resistance of single crystal diamond, but also has the advantages of polycrystalline diamond wear resistance and low price. It has achieved good results in replacing rare natural diamonds in the preparation of wire drawing die tools. Its widely use will bring new vitality to the wire drawing die industry.

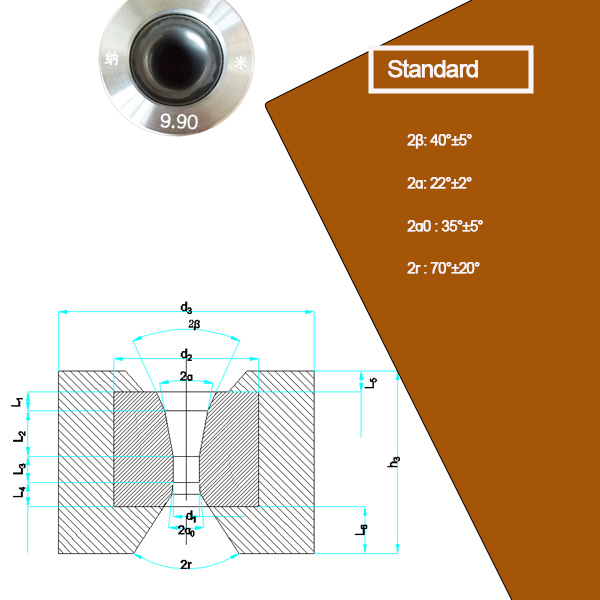

Process and technology:

Targeted pretreatment process:to make the coating and the substrate closely combined

Micro diamond coating:excellent wear resistance

Surface of nano diamond coating:excellent surface finish and low friction coefficient.

Optimization of pass design by computer

L5(Entrance) | The inlet area is polished so that the drawing fluid can circulate smoothly |

L1(Approach) | The lubrication area is finely polished, so that the wire can be easily excessive |

L2(Reduction) | The working area can reduce the drawing force, and the change-point contact is face-to-face angle drawing, which reduces friction and die wear. The deformed structure is more reasonable and stable. The upper line can be drawn smoothly when the incoming line becomes thicker or thinner. |

L3(Bearing) | The fixed warp area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time. |

L4(Back Relief) | The safety angle can ensure that the wire is drawn without scratches, and the life expectancy tends to be longer. |

L6(Exit) | The deepening of the outlet can greatly support the tensile stress of the outlet. |

The advantages of NANO Diamond Coated Wire Drawing Dies are as follows:

1.Long service life:the service life of copper aluminum wire,low carbon steel wire,medium carbon steel wire,cable stranded wire,welding wire and die is 20-30 times more than that of cemented carbide mold,and that of cable stranded wire is more than 50 times that of cemented carbide.

2.The size control precision is high,the wire size is stable,and the size consistency can be maintained for a long time.

3.The inner hole of the mould is bright,the self lubrication is good,the surface friction coefficient is small,the surface finish of the wire rod is high,the material is not sticky,the quality of the finished wire is good,and the loss of equipment and equipment can be reduced at the same time.

4.The length of wire is 1% - 2% longer than that of traditional mold.

5.Repair free mode, maintenance free,reduce the number of downtime detection,mold change,greatly improve production efficiency,unit time production significantly increased,saving a lot of labor costs.

6.It is suitable for drawing process without pickling,environmental protection and energy saving.

CATALOGUE