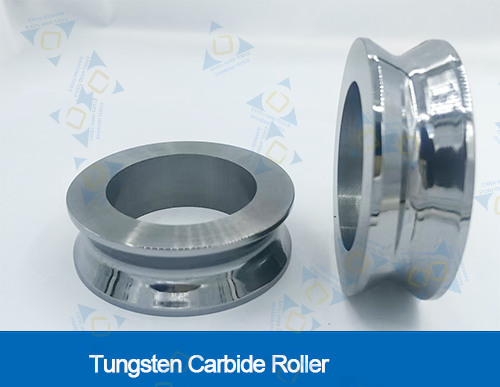

Cemented carbide roller in the cemented carbide factory should be more common, mainly installed outside the bearing, when the wire goes through from the groove surface, the roller rotates when the wire passes by, thereby converting sliding friction into static friction. Carbide rollers are mainly used in wire manufacturers in the metal products industry, such as wire, cable, steel wire rope, stainless steel screen and other production enterprises, can also be used in textile, chemical and other industries. Today, we will share with you the performance characteristics of cemented carbide roller, as well as its heat treatment method.

Carbide roller refers to one or more refractory metal hard carbide and binder metal, through the powder metallurgy process to produce a class of alloy materials. The performance characteristics of cemented carbide roller are mainly manifested in:

1. carbide roller has high hardness, good wear resistance of carbide, carbide roller hardness at room temperature up to 86~93 HRA, under 900~1000℃ temperature still has a high hardness, so when carbide roller is in use, its cutting speed, wear resistance and life are significantly higher than high-speed steel.

2. The compressive strength of the carbide roller is higher than that of high-speed steel, but the bending strength is only 1/3 to 1/2 of that of high-speed steel, and the toughness is poor, about 30% to 50% of the hardened steel.Carbide roller heat treatment process:

Tungsten carbide roller is made by mixing tungsten carbide and cobalt in a certain proportion, pressurizing into various shapes, and then semi-sintered. This sintering process is usually carried out in a vacuum furnace. It is placed in a vacuum furnace to complete sintering, at a temperature of about 1,300 to 1,500 degrees Celsius.

Carbide roller sintering molding is to press the powder into billets, and then into the sintering furnace to heat to a certain temperature (sintering temperature), and maintain a certain time (holding time), and then cool down, so as to obtain the required performance of the carbide roller.