Shrink pipe die is a tool commonly used in the field of metal processing, its principle is to use the mold to compress the metal pipe, so as to achieve the effect of reducing the diameter of the pipe. In this way, the originally thick pipe can be made more slender.

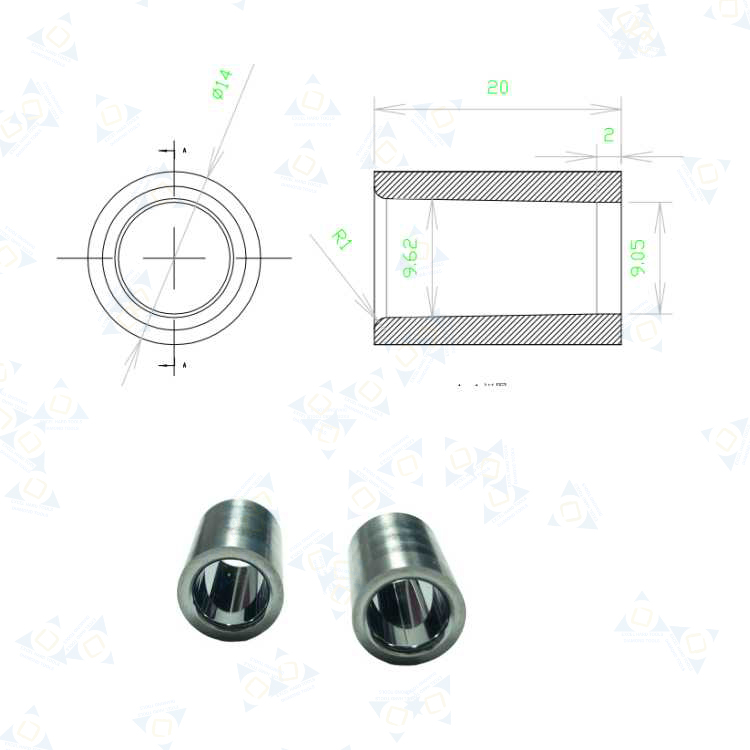

The core part of the tube mold is the mold. Molds are usually made of high-strength alloy materials with certain hardness and wear resistance.

The internal profile of the mold matches the desired shape of the pipe, and the pipe can be compressed into the desired size through the pressure action of the mold.

The working principle of the shrink tube die is to use mechanical force to place the tube inside the die and apply the appropriate pressure. In the process of applying pressure the pipe will be squeezed by the internal mold, which will gradually reduce the diameter of the pipe. By controlling the amount of pressure and the time applied, precise control of pipe diameter and wall thickness can be achieved.

The shrink tube mold can also be controlled by the temperature of the mold to achieve more fine tube processing. In some special cases, heating the mold can make the metal

material softer, so that it is easier to be compressed and processed. In other cases, the cooling mold can quickly solidify the metal material, making the shape of the pipe more

stable and precise.

The principle of shrinkable tube die has a wide range of applications in the field of metal processing. The precision processing and forming of the pipe can be realized through the shrink pipe mold, which is widely used in automobile manufacturing, aerospace, construction engineering and other fields. Its efficient and accurate processing ability makes the tube mold an indispensable tool in modern industrial production.

In general, the principle of the pipe reduction mold is to compress the metal pipe through the pressure action of the mold, so as to achieve the effect of pipe diameter reduction.

By controlling pressure, temperature and processing parameters, precise control of pipe size and shape can be achieved to meet different process and design requirements. The tube mold plays an important role in modern industrial production and promotes the development and progress of metal processing technology.